I’ve recently been fascinated by the idea of sous vide cooking – a method of slowly cooking vacu-sealed foods in a precisely controlled water bath to achieve the optimal doneness. Last year, Sur La Table started carrying the world’s first “home” sous vide cooker, the SousVide Supreme. This was fantastic, since commercial sous vide cooking machines cost north of $2000. However, the home model (priced at $450) is still a steep investment for something that essentially just keeps water warm. I was determined that I could build a better device on-the-cheap.

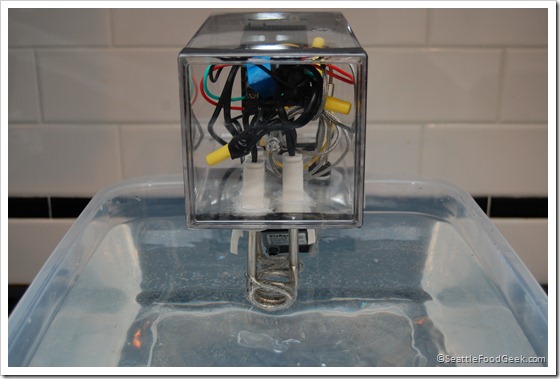

Behold, the $75 DIY sous vide heating immersion circulator! By scrapping together parts that are readily available on eBay and Amazon, I was able to build a self-contained device that heats and circulates water while maintaining a temperature accurate to .1 degree Celsius (yes, point one degrees!). And unlike the SousVide Supreme, my device can be mounted onto any container (up to a reasonable size, perhaps 15 gallons) allowing you more room to cook, if needed.

To build your own device, you’ll need some basic soldering skills, the list of stuff below, about 6 hours of free time (plus time for glue to dry) and the can-do attitude of a geek who doesn’t want to pay $450 for a water heater. Click the “more” link for complete step-by-step instructions.

If these instructions have helped you build you own machine, I hope you’ll consider donating. My goal is to mass-produce the world’s first sous vide heating immersion circulator for under $100, and every donation helps!

Makes: 1 sous vide immersion heater

Total tinker time: about 6 hours

Shopping list:

- Clear Storage Container – Medium $4.95

- 3x NORPRO 559 Immersion Heater for Warming Liquids $17.97

- 79 GPH Fountain, Hydroponics, or Aquarium pump- VA80 $9.99

- PID Temperature Controller with SSR Output $39.50 (I’ve found similar controllers on eBay for under $30.00, but this one is very popular among builders of this project)

Note: Make sure the controller you purchase has an SSR or Voltage output. Controllers with a relay-only output will require an external relay and different wiring than what is listed in this project.

- PT100 Thermocouple Probe $5.99

- SPST Heavy-Duty Rocker Switch $2.99

- 7-9VDC/12A SPDT Relay $4.49 (Only use if you have a CD101 PID controller and want to save a few bucks over buying the SSR)

- 25A Solid State Relay, DC Input, AC Output $14.50 (Necessary for the JLD612 PID Controller)

I’ve updated the parts list to specify an SSR – it adds a little to the cost of the project, but it is far more reliable, easier to connect, and works with any SSR/Voltage-output PID controller.

- 1 piece of 1/4” acrylic, about 5cm x 20cm

- 1/4” x 2” eye bolt and nut

- About 2’ of 16-18 gauge wire

- 3 wire nuts

- Electrical tape

- A means of cutting acrylic (see article)

- Soldering iron and solder

- Multimeter (tool that measures voltage, current, resistance)

- Hobby knife (X-Acto or similar)

- Tub and Tile Silicone Caulk

- Hot glue gun

- Krazy Glue

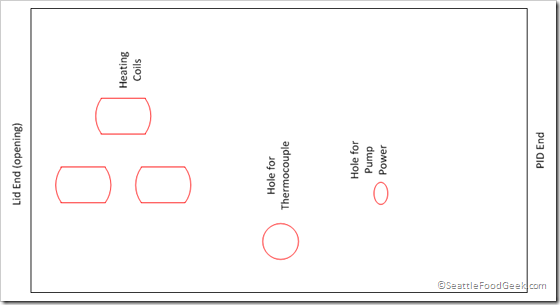

Step 1 – Making cutouts in your enclosure

This is the most difficult part of the whole project. In order for the final assembly to be sturdy, water-resistant and decent looking, you’ll need to cut your mounting holes as precisely as possible. I am very lucky to have access to a laser cutter at a lab at work, which makes this kind of precision cutting very easy and accurate. However, in the absence of a $30K computerized laser cutting machine, with a steady hand, you can achieve the same results using a high-speed rotary tool like a Dremel.

I’ve included a cutting template that is matched to the heaters, PID controller and switch in the shopping list. However, if you use different parts (different models, different manufacturers) you’ll need to adjust the template to ensure a tight fit of all parts.

Click here for the 1:1 scale diagram (PDF)

Click here for the 1:1 scale diagram (PDF)

- Pick a side of the storage container that you want to be the bottom. Using the template as a guide, cut out the three holes for the immersion heaters. Make sure that these holes are closest to the open end of the container (the end that has the lid) to ensure you’ll be able to reach inside later for wiring, etc.

- Next, cut the small oval-shaped hole for the water pump power cord.

- Turn the container over so the side with the holes is facing down. Now, cut out the openings for the PID controller, the on-off switch, and the power cord. Be sure that the hole for the PID controller is towards the top. Otherwise, you’ll be cramped for space when trying to reach the back of the controller.

- Next, dry-fit all of the parts to ensure a good, snug fit. The tighter the fit, the more sturdy the finished product will be.

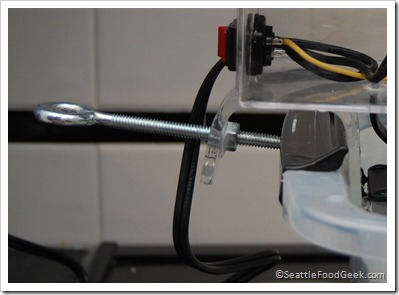

Step 2 – Making the mounting bracket and pump holder

The mounting bracket is a J-shaped piece of acrylic that will let you attach the finished sous vide cooker to the side of a pot or basin.

- Cut out the rectangle on the 2nd page of the parts diagram and drill the hole as indicated.

- Find a rectangular surface that will allow you to make the 2 90-degree bends necessary to shape the acrylic into a “J”. I used a small, glass olive oil bottle with flat sides and rounded corners.

- Turn on your stove. Holding the long end of the acrylic with an oven mitt, warm it a few inches above your stovetop, turning to heat both sides. It may take a few minutes for the acrylic to be warm enough to bend- you’ll know you’re getting close when the acrylic starts to curl away from the heat.

- Bend the acrylic along (approximately) the lines indicated in the diagram to form a “J”. Press the bottom part of the J (not the side with the hole, and not the long side) against a flat surface such as your counter top. Immediately cool the acrylic with cool water to hold its form.

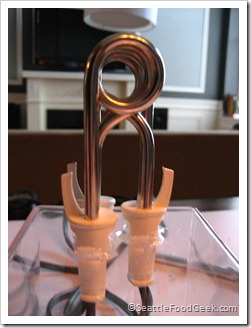

Step 3 – Mounting the immersion heaters

The immersion heaters are the primary working element of the sous vide machine. We’ll mount them hanging down from the bottom of the enclosure, and arranged so that the opening in the middle of the coil is lined up between all three heaters.

- Cut the power cord off of each heater, leaving about a 4” tail of wires from the heating end. Keep one of the long lengths of power cord (including the plug) to use later as the main power cord.

- Using your hobby knife, scrape down the flat sides of the heater handles to remove lettering and to flatten out the circular rim at the top of the handle. This will allow for a deeper and tighter fit in the heater openings.

- Arrange all three heaters in their respective openings. Note that the heaters should be oriented such that the coils are facing towards the center-line of the enclosure. You should be able to fit your finger down the middle of all three coils. Make sure the heaters are snug in their openings.

- Apply a small bead of tub and tile caulk around the heaters on the outside of the enclosure. Allow to dry overnight before proceeding.

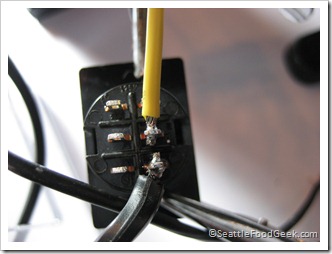

Step 4 – Wiring

CAUTION: Don’t ever power on the heater coils unless they are submerged in water! Also, don’t electrocute yourself.

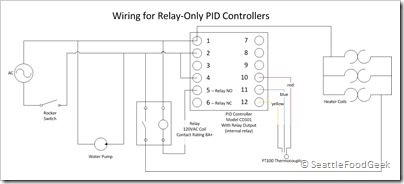

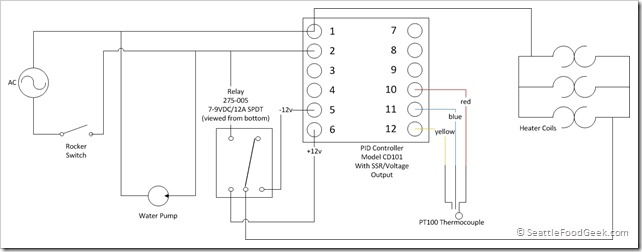

If you have experience with basic circuitry and wiring, this will be pretty easy. However, if you’ve never worked with a soldering iron or circuit diagrams, these steps will take you a while. Refer to the wiring diagram below for the “big picture.”

Wiring diagram for JLD612 PID Controller with SSR

Wiring Diagram for CD101 PID Controller with physical relay

Update: I’ve updated the wiring diagram to make it clear that the view of the relay posts is from below. In other words, if you set the relay down on your table with the pins facing up, that will match the alignment in the wiring diagram.

- Strip off about 1/4” of shielding from your power cord (remember, the cord that you saved from one of the immersion heaters?). Run the power cord in through the power cord opening on the front of the enclosure. Separate the 2 wires about 6”. One of these wires will go through the power switch, and the other will go directly to the PID controller, heaters and pump.

- Use your multimeter to find the two posts on the back of the power switch that are normally open, but closed when the switch is on. On my power switch, these were the far and middle posts (not the two posts closest to the “ON” side of the switch, you know, with the dot).

- Pass the switch mounting nut (the thing that screws on the back) over one lead from the power cable, inside the enclosure. Run the lead out through the power switch hole. Solder that lead to one of the posts you identified in step 2. Cut an 8” length of wire and solder one end to the 2nd lead on the switch. Tuck the wires inside the enclosure, place the switch in its hole, and tighten the mounding nut to secure it in place. You’re now done with the power switch.

- Next, wire together the heater leads. Separate the leads from the heating coils. Gather together one lead from each coil to make two bundles of three. Cut two 6” lengths of wire and add one to each bundle. You should now have two bundles, each with four wires – 3 of which go to the heaters, and one left dangling. Solder the wires in each bundle together, then cap with a wire nut and some electrical tape.

- Of the leads you have coming out of the heater bundles, one will go straight to the incoming power, and the other will go to the relay that turns on and off the heaters.

- At this point, it gets too difficult to describe the rest of the wiring in words, so refer to the wiring diagram. Just make sure to be aware of how everything will mount in the enclosure when you’re all done. Pass the wires through the mounting ring on of the PID controller before attaching them to the terminals, etc.

- After wiring the connections to the relay (or SSR), coat the bottom with hot glue to surround the connection points. This will act as an insulator and prevent the relay from shorting out against any metal inside the case. Or, if your SSR came with a plastic cover, secure it in place to prevent the connections from shorting.

- If you are using the PT100 thermocouple (which I recommend), make sure you connect the leads exactly as shown in the wiring diagram or you will have an inaccurate temperature reading. (There’s no instruction manual with these probes, so it took 30 minutes of trying different combinations before I found the right one).

Step 5 – Final Assembly

- Using Krazy Glue, glue the J clamp to the bottom-front of the enclosure. Wait until dry before proceeding.

Note: This glue joint is a popular point of failure. If you’d like, strengthen the connection between the J clamp and the body by using two screws and nuts. - Glue the nut for the eye bolt to the inside of the hole in the J clamp. Ensure that the nut lines up with the hole so the eye bolt can pass through.

- Seal the openings for the power cord and pump cord using tub and tile caulk.

- Put the back cover on the enclosure and wrap the seam with electrical tape.

- Stick the suction cup feet of the immersion pump to the flat end of the J clamp and position the water outlet to pump through the middle of the heating coils.

Step 6 – Testing

Now that everything is wired up and assembled, you probably want to see if it works. WAIT! Don’t turn the machine on (ever!) unless the coils are submerged in water or, they will burn out in about 5 seconds (I learned this the hard way).

To test the machine out, fill a basin with water so that it covers at least the coil part of the heaters. Mount the machine on the edge, so that the J clamp hangs over the lip. Tighten the eye bolt to secure the machine. Plug in the cord and flip the power switch! If the PID controller turns on and the pump starts pumping, that’s a good sign! Note that the heaters may not warm up just yet, depending on what the target temperature is by default.

Step 7 – Programming the PID Controller

For users of the JLD612 PID Controller

For programming instructions such as running Auto-tune and changing alarm values, refer to the JLD612 manual. Here are the steps you should take when programming your controller for the first time.

- Press SET and enter code 0089, then press SET.

- Set the value of Inty to Pt10.0 to get the temperature to display with one decimal place. (I had to set it to Pt100, then back to Pt10.0 to get this to work the first time.

- Select End to exit the programming menu.

For users of the CD101 PID Controller

Out-of-the-box, the PID controller is designed to work with a different type of thermocouple, so the readings that you get using a PT100 will be strange. Follow the instructions in this manual (that doesn’t ship with the PID controller) to set it for the PT100 probe. You can also follow the instructions there to set the number of decimal points of precision.

Next, set a target temperature by tapping the SET button, then using the up and down arrows to pick a number and pressing SET again to confirm. 50C is a good target temp. The OUT1 light will light up, indicating that the PID controller is turning on the heater. You should hear a soft clicking noise – this is the relay kicking in. At this point, the heating coils are on and warming up. As the temperature measured by the probe (green, top line) approaches the target value (orange, 2nd line), the relay will click on and off more frequently to sustain the temperature..

Ideas, Improvements, Thoughts

After burning out my first set of heating coils, I realized that there must be a better method of heating the water. The coils are very effective and heat the water very quickly. However, I’m pretty paranoid about burning them out again, and they’re a pain to replace. I’ve found some commercial immersion heating elements, but they’re about $100, which inflates the budget for this project by quite a bit. I may try using the heating element and pump system from an old espresso machine, the kind that makes steam. Since it already has a self-contained heater and an pump, it might even be cheaper than the heating coils and aquarium pump.

I’ve also thought about turning this machine into a general-purpose temperature control unit. Instead of wiring the heaters directly to the relay, I would install a power outlet on the back of the enclosure and add a jack to plug in an external temperature probe. If I wanted to use the immersion heaters, I’d just plug them in to the power outlet. If one got fried, I’m only out $6 instead of an hour of removing glue and solder. Also, a general-purpose temperature controller is great for making your own smoker box. A-la Alton Brown, you can plug in a hotplate filled with wood chips and have a precisely temperature-controlled smoker for just a few bucks.

I’m thrilled to start playing with sous vide cooking, and I’m happy that I was able to build an accurate, reliable machine for $75. Even the PID Controller + Crockpot method costs $185 (not including the Crockpot!).

Troubleshooting

I gotten a lot of emails and comments asking for troubleshooting help, and rightfully so – there’s a lot going on in this project, especially if you’re pretty new to DIY electronics. I’ve decided to add my basic troubleshooting routine, which should hopefully get you sorted out. If you still have problems, please post a comment below, or send me an email at scott@seattlefoodgeek.com.

If your heaters don’t get hot when they should (i.e., your machine isn’t working), do the following:

- Ensure that your OUT1 light goes on and off when it should. It should be on when the unit is heating, and off when you’re at or above the set value. If not, double check that you’ve set your temperature probe type correctly, and that OUT1 is set to heating mode in the PID settings menu. If this looks correct, proceed to step 2.

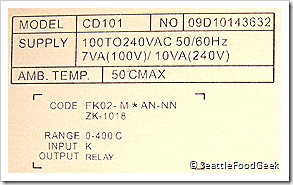

- Verify that your PID controller has an SSR/Voltage output. This should be specified on the sticker on the side of your PID controller. The controller in the photo below only has a relay output (this is not what you want).

PID controllers generally have two types of outputs: relay and voltage. Contrary to how it sounds, a relay output is not used for controlling a relay. Rather, a PID controller with a relay output actually has an internal relay. Unfortunately, the internal relay is typically not rated for the kind of load that the heating coils pull, so you cannot connect them directly to the internal relay. A PID controller with an SSR/voltage output produces a DC voltage (8-12V DC) that we can use to control an external mechanical relay or a solid state relay (SSR). That’s what we want.

Telltale signs that your PID controller has a relay-only output: a) there’s no voltage across pins 5&6 (or the corresponding pins on your controller) when the OUT1 light is on, b) you hear a clicking sound when OUT1 turns on and off, even when your external (blue) relay is disconnected, and c) you measure continuity across the pins that correspond to OUT1 when OUT1 is on.

If you have a PID controller with a relay output, not all is lost. You’ve got two options:

1) Return it for a PID controller with an SSR/voltage output, or

2) Use the internal relay to control an external 120VAC relay that is rated for 8+ Amps @ 120VAC. The wiring for this configuration is a little messier, and you’ll need to buy a different relay than the one specified in the parts list. The wiring diagram for this configuration is below. Note that I haven’t attempted to show the actual pin configuration of the external relay – rather this is the logical way you’ll need to wire it in.

If you’re sure that your PID controller has an SSR/voltage output, proceed to step 3. - Verify that you are using the right kind of relay for your PID controller. The CD101 will work with either an SSR (solid state relay) or a physical relay. However, the JLD612 and many other PID controllers will only work with an SSR.

- If you’re using a CD101 and a physical relay, ensure that your external (blue) relay is wired correctly. You should hear a clicking noise coming from that relay when OUT1 lights up or turns off. If not, you may have connected the leads from pins 5 & 6 backwards, or your external relay may require a higher activation voltage than what your PID controller outputs. Measure the voltage from pins 5 & 6 and compare to the coil voltage specified by your relay. In practice, there is some wiggle room (ex., a relay with a 9V coil will often be activated by less than 9V). If the PID doesn’t produce enough voltage, buy an SSR. If your relay is clicking, proceed to step 5.

- Check for 120VAC going to the heater leads when OUT1 is on. If you’re not seeing a voltage, check the connections across your relay and between pin 1 and your heaters. If you’re getting 120VAC to your heater bundles, proceed to step 6.

- Your heaters are likely burnt out. This can happen in a flash if you accidentally supply power to the heaters when they are out of water. Double check by submerging your heaters and connecting an 120VAC power source directly to the leads (exercising great caution not to electrocute yourself). If they heat up, you’ve got a loose wire somewhere in your connections. If they don’t heat up, they’re burnt out and you’ll need to replace them.

If these instructions have helped you build you own machine, I hope you’ll consider donating. My goal is to mass-produce the world’s first sous vide heating immersion circulator for under $100, and every donation helps!

I’m in awe, bro. You were telling me about this at the Palace Kitchen meetup. The package you built looks completely pro, and I love that you even included templates for making the cuts.

I am soooo impressed! I just got a vacuum sealer for Christmas and was wondering how I could build a sous-vide machine. This is awesome!

Just saw this, wondering if you have any take on how effective this might be:

Woops, that didn’t work…

http://voices.washingtonpost.com/ezra-klein/2010/02/lunch_break_113.html

Nice – always a fan of the home brew solution!

The microwave technique looks cook and is certainly more convienient. But if his microwave is anything like mine, it has cold spots and warm spots. So there’s a risk of scorching one part of your veggies and leaving the rest undercooked.

I’m definitely going to try this.. For those in Seattle, you can user the laser cutter at Metrix CreateSpace (http://metrixcreatespace.com/) to cut the acrylic. It takes a little work to create the files, but it’s probably a lot easier than making the cuts by hand.

First of all, love the article. Great timing as I was just about to start on my own sous-vide setup. This will save me a lot of money over my current plans. I assume one could use the PID/thermocouple directly with a rice cooker/crockpot if you already have one of those correct?

What do you think about using the following as the heating element. 2x the price but has the advantage of being a single unit, same net wattage, designed for large volumes of water, and could be more reliable?

http://www.amazon.com/Allied-Precision-742G-Bucket-Heater/dp/B000BDB4UG/ref=sr_1_11?ie=UTF8&s=hi&qid=1265139316&sr=8-11

Simon, I’m so glad to hear that you’re planning to try this out! I’ve converted the scale drawings to SVGs to make them easier to use with the laser cutter at Metrix. You can download a zip of the files here:

https://seattlefoodgeek.com/wp-content/uploads/2010/02/cutout-drawings-SVG.zip

Yish, I looked at this heater too, but after I had already committed to using the immersion coils. It does look like it would do a better job and would be more rugged (and you wouldn’t have to worry about accidentally burning it out). If you decide to order one, I’d love to hear your impressions! Perhaps that heater will be a good investment for version 2.

You’re my hero. I can’t believe you built this on the cheap. You go, Seattle Food Geek.

Very interesting machine! what about the precision of the temperature and the stability, what kind of equipment did you use to verify there parameters? Did you make a long period trial of your immersion circulator?

Jean-François

Hi Jean-Francois,

I compared the temperature reading on the machine to three other thermometers that I have and know to be accurate. You can also verify the accuracy of the temperature by measuring the temp of boiling water (which should always be 100C) and very cold ice water (which should be close to 0C). The PID controller allows you to specify a correction factor if the thermocouple is reading an innacurate measurement.

I let the machine run for about 45 minutes once it had brought the water to 50C. I monitored the temperature reading and it never deviated during those 45 minutes, even by .1C.

The PID controller has an “Autotune” mode that I ran before my test. This mode turns on and off the heaters and measures the temperature change from heating and cooling. Based on the measured change, the PID controller optimizes itself automatically so that it can maintain an exact temperature. Pretty neat stuff!

Just out of curiosity, at what temperature would the pump start having problems? I’m currently using a PID on a crockpot, and do 8 hour cooks at 180F for duck confit. I’d be worried about the pump operating at that temperature.

Hi Andrew,

That’s a great question. I don’t know (yet) how the pump will perform in hot water over long time periods, but I’ll test it out and report back!

I have been thinking hard about this all day and i keep coming back to a small replacement hot water heater element…they are cheap, around the same as three of the tea cup heaters, a possibility? only one round hole to cut (much easier) and it is threaded and has a gasket.

thoughts?

Also, with the design you have now, if a bag were to touch the elements would it melt/break? a guard perhaps to prevent that would be great. some sort of wire basket?

Dear Scott,

Several of us are meeting in Atlanta on 2/21/2010 to do this together. Would love to be able to reach you w/a question that day! Lol, we’ll see how it goes! BBQ will be on hand.

Best,

David

WOW. Incredible stuff mate. Truly unique I have to say! I have never considered making an immersion circulator, but now feel like I have to! Talk about a cost saving too – I cannot believe how cheaply you were able to build this!! (Heck mate, you should start making them for us Seattle food people!)

I’m excited to learn more about sous vide! Do you know of any restaurants using this method? What foods are most beneficial when cooked this way?

Hi Speckle,

I know of a few Seattle restaurants, like Tilth and Spur, that use the sous vide method for several of their dishes, but I suspect that there are many more out there. I’m still pretty new to the technique myself, but I’m dying to explore the frontiers that it opens up in the kitchen.

As far as what foods to choose to cook sous vide, the classic examples are fish, beef, and eggs. In all three cases, the precise control over temperature allows you to achieve a perfect doneness. I’ve eaten sous vide vegetables, like beets and carrots, but the difference isn’t nearly as dramatic.

I just ordered Thomas Keller’s sous vide cookbook, so I’ll be sure to post my findings!

You rock!! I’m sure the SeaTac folks would be concerned if they saw it, and one might wonder if you cross wires, you wind up back in the 1950s with a young George McFly, but who cares, as this is a truly awesome device!

I’ve gathered almost all the parts on your list…just waiting on my PT100 Thermocouple to come in…hopefully tomorrow.

Interested in the idea of wiring the 120v outlet onto the unit instead of hardwiring the immersion heaters…would you just use a standard style plug like this:

http://www.homedepot.com/Electrical-Outlets-Plugs-Outlets/h_d1/N-5yc1vZ1xr5Zbm78/R-100666180/h_d2/ProductDisplay?langId=-1&storeId=10051&catalogId=10053

or did you have something else in mind?

Is there any concern around the need to plug a 3 outlet adapter into this to accommodate all 3 heaters? I suppose it’s all the same as hardwiring them, but my electrical knowledge is very meager.

Also, I would like to use a switch like this:

http://www.radioshack.com/product/index.jsp?productId=2062493

I remember i used to have one in my car, but i don’t know how to get it to work…relay? Can you provide a wiring guide for that? Maybe this will work…

http://www.radioshack.com/product/index.jsp?productId=2062506&filterName=Type&filterValue=SPST

Also is 6a 125VAC the minimum switch rating you recommend, Radioshack has a 5a 125VAC that I think i can get a “rocket switch” cover for…they’re just cool.

Hi Alvin,

Glad to hear you’re going to take on the challenge of building your own immersion circulator! If you’re going to put in an outlet (or three), I’d recommend 2 things: 1) use an outlet that is designed for outdoor use or use in damp areas, and 2) use an outlet with a built-in GFI (ground fault interrupt). You’ll know if it has GFI because there will be a small reset button built right into the face of the outlet.

And, of course, be careful. There’s a lot of power resting a few inches above a big pool of water. I’m not sure what I need to write (legally) to make sure I’m off the hook if you shock yourself, but consider yourself warned 🙂

As far as the switches, you should be fine with either one. The Radio Shack website doesn’t have wiring diagrams, but they’ll wire in in just about the same way as the switch I used. You can use a multimeter to test which posts to solder to – when the switch is off, there should be no electrical connection across 2 of the posts. When it is on, those two posts will pass current.

Best of luck, and report back when you’re done!

-Scott

Thanks for the quick response Scott…

No PT100 today, so I guess i have a bit more time to plan.

had the same thought of the danger in the design. I thought about building some type of legged platform for the ddevice to rest on rather than the clamp…i suppose that with the outlet it wouldn’t have to be on top of the container and it could be next to it instead…

for the plug in temp probe were you just thinking of using some type of TRS connector?

Saw your steak pic, have you used yours for anything else? what type of heat (if any) does the box itself create?

@alvin, Yeah, I was thinking about a TRS style connector… maybe something designed for moisture & corrosion resistance. As for the enclosure, it doesn’t generate any noticable heat. You’ll want to make sure all of your holes on the underside of the box are well sealed with caulk, though, since the basin will give off a fair amount of steam.

So far, I’ve stuck with steak (life changing!) but I’m going to play around with other things as well. Just got Thomas Keller’s “Under Pressure” sous vide cookbook which has amazing recipes.

@Scott, do i have to ground the GFCI outlet? would that mean running a 3 pronged plug to the wall and connecting the ground directly to the outlet?

@Alvin Exactly. Note, however, that I’m not an electrician and should be considered unqualified to give such advice 🙂 But, that’s how I would wire it if I were you.

I had a pretty busy day off…

http://www.facebook.com/album.php?aid=47864&id=1523087481&l=0ecc37f6e1

Amazing,

I am currently working on a version myself but I think I should scrap it in favor of something similar to yours.

For some reason I felt that the heating element and the circulating element should be in one system. I pumped water through some copper coiling around the heating element from a hairdryer. It works but the heating and control is too inconsistent. Not to mention, it wasn’t throttling water enough.

Hi Scott,

Can you please post the settings on you PID?

I am sooooo close i can taste it. When my “OUT1” light comes on, i hear clicking (from the PID controller) but i get no reading on terminals 5/6.

Also, should I expect continuity on the coil terminals of the mini-relay? i get no tone on them right now.

Thanks for your help!

Scott, you are brilliant and I’m in awe!

Thanks for your work pioneering this DIY project. I recently became interested in this cooking style, but I didn’t want to spend a lot of money on a dedicated cooker and I am always interested in DIY projects. I designed mine a little differently. I wanted to have plugs so that I could easily change heating elements or just use a slow cooker. I use an old crock pot last night for my first test and it worked well.

I ended up with a slightly different PID than you did. The link you have for it did not come up with anything but I found some on E-Bay that looked the same. The one I got is the same model – CD101, but is configured differently and it came with a thermocouple. My PID has a relay built in instead of a 12v trigger on pins 5 and 6. Of course I didn’t realize this until I had already bought the relay. Mine also came with a 4 page instruction manual, but the manual leaves out how to change the parameters. My PID also has some different parameters, and I cannot change the number of decimals it displays, so it is stuck with 0 decimals.

I wanted to keep it easy to start with, so I just took an 8 foot extension cord I had around with 3 outlets and cut it in half. I wired it into the PID so it controls the 3 outlets. It really could not be any simpler.

The thermocouple it came with is really stubby, maybe half inch but seems to measure accurately. I had already order the probe that you used before I realized that the PID came with one, so I will probably change to that probe when it gets here.

The only issue I have right now is the reading from the thermocouple (PV) drops 3-4 degrees every time out1 goes off. I think there must be some kind of electrical interference and I’ll play around with it to fix it. My instructions talk about twisting the power leads and minimizing the distance to avoid interference. It also says that you need to have a 250 ohm resistor on the input which I do not currently have.

Avlin – it sounds like you have the same kind of controller as me, with the relay built in if you hear clicking. To test, take a volt meter and see if you get any voltage across pins 5-6 with out1 light. If not, then test for continuity between pins 4-5-6. Pins 4-6 should have continuity with out1 off, pins 4-5 should with out1 on. Let me know if you need help wiring it.

I would love to hear more about what heating coils you have used that seem to last. I plan on experimenting with those next.

@Jon: Yes! That worked…mine also has the built-in relay…wiring hot from the main switch on the box to #4 and out on #5 to my GFCI socket…some fine tuning and i think it’s steak for dinner tonight. I hope to finish a write up soon of my process and i will try to include some instructions on how to set accuracy and move the decimal place. I think i used Scott’s instruction link to move the decimal, but i was flipping through so many resources i may not have…

@Jon Nice, I’d love to see your solution! I may build a second, general purpose unit with outlets to make a DIY smoker or a chocolate tempering machine. For my heating coils, I’m still using the 3 immersion heaters listed in the instructions. So far, I’ve got about 10 hours of cooking logged on them and they’re still going strong. Just have to be cautious never to turn on the machine unless the coils are submerged. I’m actively investigating finding an upgrade to the coil solution, though.

@Alvin Awesome! Please send pics when you’re all done. I’d love to post a gallery of the DIY adventurers who took on this challenge themselves!

FYI- the “AT” or “Auto Tune” setting is your friend…forget about the Jay Z song…mine finally seems to be holding a temp.

http://tnrplaya.wordpress.com/

To streamline things and because I figure it is the component most likely to give out, I may just leave the pump as a stand alone component. I will still mount it exactly like you did but just plug it into the wall separately. Is there any reason that should cause me any issues?

@Alvin Congratulations! It looks awesome.

@Pete W Nope, no reason to worry about the pump. I’d actually imagine that these little pumps are pretty reliable. Since they’re fountain pumps, they’re designed to be left on continuously. My coworker had a mini fountain in his office that he left running for months on end. But, there’s no harm in wiring it separately, just in case.

So, I saw your tweet about sourcing parts for “manufacturing” these. Where do I sign up to buy one?

Thanks

Hank

@Hank Great question! if you’re interested in buying one of these (hopefully ready to sell in a few weeks) shoot me an email at scott@seattlefoodgeek.com.

Thanks!

Trying to get my buildout finialized, but I’m not sure if I’ve got everything correct. I’m not electronically inclined at all, so I’m not able to pinpoint where I may be going wrong.

If anyone could take a look at the manual for me and let me know if it has an internal relay, or do I need to use a relay like Scott has? link: http://www.lightobject.info/viewtopic.php?f=13&t=3

I may have some other questions, but I think I’ll start with that one.

@W It’s best to use a relay, since usually the relays built into these controllers are only rated for switching about 375W, and your heaters add to 900W.

If anyone has had success using the relay built into the controller, please let me know, as it would be great to save a solder connection!

I see you are very committed to your sous vide cooking. Fantastic idea and great article!

Scott,

Any other ideas on where to source the PT100 probe? The company that sells them on ebay is backordered and has no idea when they will get more (though this has not stopped them from listing them on eBay).

I got my PT100 probe, which ended up being the hardest part, and the controller works much better now. Looking back, I don’t think I had the other probe wired correctly now and that was causing my temperature fluctuations. You need the PT100 probe if you want the display to show 1/10 of a degree. I’m guessing that the k-type thermocouple cannot measure that precisely. I also figured out how to get it to display in Fahrenheit, but that ‘broke’ when I changed temperature probes. I’m guessing there is a bug when it tries to convert decimal places.

My little crock pot setup has been working great so now I am trying to decide whether to go with the immersion heaters or a large (18+ quart) counter top roaster oven. I like the flexibility of the immersion heaters, but I also like the simplicity of a self contained unit.

@Scott You have me a little scared about the built-in relay now. Mine has been working fine controlling a small crock pot but I might augment it with a larger one before I add more power.

@ Pete W I searched for a while before I found a source for the probe that wasn’t outrageously expensive. I got this probe http://www.grainger.com/Grainger/items/2HMP6?Pid=search but I have a local Grainger store. This place has it too with free shipping: http://www.drillspot.com/products/466574/Love_S-11_Temperature_Probe

The probe only has 2 wires so connect it to terminals 10 and 11 and jumper 11 and 12.

hi scott

i’m thrilled to see this. can you built one for me. i’m a full time cook and have no time and knowledge about electricity. i thought of buying a professional but the restaurant can’t afford it. it’s a wondermachine. what this thing does to proteins is beyond we’ve known about cooking. i had a machine for two days and putted in everything i had, fish, tender and fat meat and everything comes out like something else. exciting. poaching was yesterday.

let me know your conditions.

gilbert

any one who has built one of these NEEDS to try eggs…just sous Vide in the shell (no vac sealing needed )@ 64.4C. incredible.

I just finished a 25hr short rib and my internal relay worked out great…

Thanks again to scott for the instructions and build!

Scott,

Just a small question for clarity. The acylic container list in your reference are 4.75″ x 4.75″ x 5.25″. However the template is 4″ x 6″. What size container did you use? I just want to order all the right pieces.

Thanks

@JT The storage container linked to in the parts list is actually 4x4x7. You should be good to go with that one.

Scott – My heating elements are touching each other – can they touch or will this short the device?

The silicone caulk isn’t firm enough to keep them from touching. I tried liquid weld but that isn’t work either.

Thanks!

@jimmy The heating elements can touch each other – that is OK. Inside the coils, there is a resistive wire that gets hot. The wire is surrounded by a non-conductive material, like a ceramic powder. This prevents any electricity from travelling to the outer part of the coil. Otherwise, you’d be electrocuted if you stuck your hand in the tub of water!

So, it is fine if your heating coils touch. They won’t short out.

Hi Scott

First of all this is the coolest homemade gadget i have ever seen.

Lately I have been reading alot about sous vide.. And i have decided that I simply have to try building an immersion circulator like yours. The problem is that I live in europe (denmark) where we have 230 v – so my question is do you think I can use your rick?

The PID should not be a problem, but what about the immersion heaters

Thanks!!

@Anders Yes, this design will still work for 230V. However, you’ll need to find immersion heaters that are rated for 230V, or are rated from 110-240V. I’ve seen a few on eBay, but you might try hardware or camping stores, or an online retailer in your area. Also, (IMPORTANT) the power output of the heater will be doubled at 230V compared to 110V. So, you may want to alter the design to only use 2 heaters instead of 3.

Best of luck!

Another question Scott. Will this work as an heating element?

http://www.amazon.com/Camco-2143-1500-Screw-Element/dp/B0006IX89Q

Thanks

@JT I’m actually working on testing that now. The upper part of the element gets pretty hot, and I need to see if it will risk melting the enclosure. Standby.

@JT I’ve finished my testing with the heating element you linked to. I got a conclusive NO 🙂 Although the element works fine, electrically speaking, the top of the element gets far too hot for the plastic housing. After less than 10 minutes of heating, mine literally melted a hole through the enclosure and fell into the water bath. Good thing this was an intentional test!

I understand the science, Acrylic does not resist heat very well. Have you uncovers any other options for the heating element or should I stay with the NORPOR559. Thanks for the help.

JT

Have you seen http://cow.org/r/?6508 as an alternative for the heating elements? I can’t quite figure out the dimensions of it, but the safety shut off is nice. To build in a safety for your version I was looking to use something like http://cow.org/r/?6509

Most of the parts have been ordered so I’ll update with my final product. I think I’m leaning toward a modular version that @alvin did.

Of course, as a friend pointed out, http://cow.org/r/?650e may be a better probe solution. When I was sourcing the parts for your method they came close to this device. Add the heating element and a pump and you’re done. Of course it takes away from the DIY fun…

Just finished my build and waiting for some stuff to dry. Thanks for the plans, Scott!

One thing I noticed during the build: I followed your instructions exactly at first but I kept screwing up the heater silicone as I was trying to move things in and out of the casing. I eventually just left them dry fitted and siliconed at the end. I think it is much easier that way.

Well I just plugged it in and it’s not working. The PID comes on, the temperature reading is correct, I’ve set eveything but even when the light says that the heaters should be on, they are not. I’ve measured across the relay and there is a current going across it. I even undid one of the heaters to make sure they were good. It worked fine when not hooked into the machine. I’ve tested every significant point of connectivity.

I am at a loss. Anybody care to help me troubleshoot this?

@Pete W

When the output light comes on, can you hear your relay click? My guess is that you have the relay wired wrong – since relays don’t generally have their pins or posts labeled, they can be tricky to wire correctly.

Test that you’re getting a DC voltage (somewhere between 5V and 12V) coming off your OUT pins (5 & 6 on my controller). If you’ve got voltage, and you’re confident that you’ve got the DC voltage wired to the correct posts on the relay, but you’re not hearing a clicking sound, your PID controller might not be putting out _enough_ voltage to trip your relay. Try connecting a 9V battery to the same pins on the relay. If it clicks, that’ll confirm it. To remedy, check Radio Shack or another source for a relay that has a lower voltage, like 5V.

Success! Thanks for your help. I did have the relay wired wrong. I was thinking the schematic of the relay was oriented as if you were looking at the bottom side (where the posts are).

Cool idea, but be careful. As a couple of people have said, you have a lot of power hovering over a bath of water.

Others have suggested a GFI plug, but I am not sure that would get you anything since there is no ground in this setup.

The best way to make this setup safe would be to use a metal box instead of clear acrylic. The ground from the wall outlet should then be wired to the metal box. Then you could use a GFI plug and even if a short occurred it should be contained within the box.

I think I’m close, but mine is having problems. The pump turns on, but the device is not heating.

OUT1 stays on all the time, the PV and SV values still don’t make sense, even after trying to program using the PDF. I’m not 100% sure I programmed it right so I will keep checking that.

When I play around with the set value, I’ve heard the relay click and OUT2 turns on.

I realize people are asking tons of questions, and it must get old, but any thoughts are appreciated.

Thanks

@jimmy Here are some debugging steps to take:

1. By default, the controller is (probably) set to Celsius. Room temperature will be somewhere around 20-25C. Hot water from the tap will be around 45. If you’re seeing wierd values from PV, you probably need to adjust the order in which your thermocouple is connected to the PID controller. The pin numbers will vary by make and model.

2. OUT1 should switch on and off when your SV and your PV are close to each other. If you set your SV a few degrees above PV, OUT1 will go off. If you set your SV a few degrees below PV, OUT1 will go on. If you’re seeing opposite results, look for a configuration setting in your controller’s manual for heating/cooling. Set it to heating.

3. If the OUT1 light is behaving correctly but your heaters aren’t turning on, make sure your relay is wired correctly. The relay should click whenever OUT1 turns on, and click again whenever OUT1 turns off.

4. With a multimeter, check the AC voltage on the leads going to your heaters when OUT1 is on. It should read around 120V. If not, your relay is wired wrong.

5. If you get a positive result with #5, you’ve burned out your heating coils somewhere along the way. It’s very easy to do – it takes less than a second of ON time out of water. Unfortunately, you’ll have to get new coils and try again 🙁

Scott – Thanks for the feedback. I did a little more testing on the device.

Out 1 is turning on because PV PV. Any idea what this means? Does it matter?

I’ll check with the multimeter next. Hopefully I didn’t burn out the coils, I’ve only turned on the device 3 times, and each time they were definitely in water.

Thanks again!

Jimmy,

Make sure you test the output from the PID as well. Despite my earlier exclamation of success (My heaters came on for the first time and I thought I had it, I didn’t). It turns out my PID was only putting out about 6.5V and it was not enough to power the magnet in the relay. I had to change over to a SSR (the Radioshack relay is actually mechanical). Now it works fine.

Scott,

One last question: if I’m getting lots of variance at different locations in my water bath as it’s warming, should I just cut up the speed of the pump or will the system just stabilize once temp is reached?

@Pete W

Yes, it’s normal for the temperature to fluctuate by location while the bath is still heating. But, once it has reached temperature (and held it for a minute or two) you shouldn’t see variances greater than -1C. Now, some variance will be inevitable: if you put a frozen steak in a warm bath, the water right around the steak will be colder. But these differences will even themselves out during the cooking time.

If you are observing major temperature variances once the bath has come up to temp, consider the shape of the bath and the placement of your machine to optimize water flow. Also, it’s not a bad idea to keep the flow of the pump set to maximum.

Could somebody clarify if the temperature controller stores away things like the PID coefficients and other settings to non-volatile memory so they don’t need to be re-entered after power-up every time? Thanks in advance.

@DeKay Yes, all of the values settable in the PID controller are stored in non-volatile memory. Power-up remembers the previous settings.

Pete W – I had the same problem as you – I was looking at the relay as if the pins were facing me.

I changed the wires and now my heaters turn on, but now I have a new problem…My heaters won’t turn off, lol. Even though OUT1 turns off on the PID, the heaters continue to heat the water.

Any ideas?

I think i blew out my internal relay… multi-meter has NO contenuity over 4/5/6 at all!

May need to swap my controller with a 12v relay out…

going to confirm with some more testing…

FYI- had at least 60 hrs on my system.

Alvin – So the PID you have has an internal relay? that’s where the clicking comes from when my OUT1 is turning on and off.

So you are going to replace the PID?

yes my PID has an internal relay. it is what clicks when out1 comes on/off…i can still hear it clicking, but I have no continuity across any of it’s terminals (no or nc)

going to try and find a replacement relay first if that’s no go, then off to a new PID…I have become to acustom to Sous Vide to give it up!

Jimmy,

That’s the exact progression of my problems (No Heaters, Heaters on all the time). Your PID is probably not sending a strong enough signal to flip the relay. You need to get a solid state relay. They can run on much weaker signals (mine can be tripped with only 3V).

Auber has a 25A that works well (it is considerably more expensive at $15).

Also, the Auber relay is nearly impossible to miswire because it is well marked and it only has normally open posts (as opposed to the Radioshack which has both normally open and normally closed).

Pete – I may check that out, though I’m going to continue to mess with this in the meantime. A friend of mine is using the exact same PID and his is working. However, we can’t figure out what’s different in our setups. I have checked for continuity and everything seems to be good.

Right now I believe am connected to the normally closed post. If I am looking at the relay, with the pins facing up towards me, the bottom three pins are all connected, and only the top right pin is connected. I am thinking I should be connected to normally open instead?

Thanks

You should definitely be connected to the normally open which is the top left if you are looking at the pins.

It’s pretty easy to check your signal from the PID with a multimeter. Just make sure you disconnect the heaters first (or have them in water). Then just turn the PID on and check to see how much voltage you are getting off the SSR posts. If it’s less than about 7V, the relay won’t work. Mine would click a lot when the system first started up but I finally figured out that it was moving the contact but not enough to complete the circuit.

Mounting this whole thing hanging over the water bath seems just plain silly to me. Put the controller & relays in a water-resistant enclosure that sits on your counter. Mount one or more outlets on it for your heating element(s), and use a temp probe that has a couple of feet of cord on it. Make a small aluminum u-bracket mount to hold the heating element(s) in position over/in the water. As for GFCI, you don’t need a GFCI outlet in your controller box as some have suggested. If you are using this in the kitchen, you will already have GFCI protection on the circuits, assuming your house was built to code. You really can’t chain GFCIs together. Most won’t work at all of they are daisy-chained. Separating the control unit from the heating until gives you infinitely more flexibility.

On a separate note, what about using an insulated cooler rather than a plastic storage tub for the water bath? Would that make it easier to maintain temp, due to less heat loss to the surrounding environment?

Hi David,

The separate controller solution seems to work well for a lot of people, and certainly has some advantages from a practical point of view. For example, as other folks have noted in the comments, you can use a crockpot as your heating source. That’s a good point about the GFI outlets, too.

I tend to prefer this design because it keeps the heating elements, temperature probe and pump nicely secured in the water bath without me having to rig something up to hold them in place. As you may know, this design is similar to how professional heating immersion circulators are built.

To your question about using an insulated cooler, it may help, but I don’t think it’s necessary. Even in a metal hotel pan, which has a large surface area and is anything but insulated, the controller is able to hold the temperature extremely stable with a very low duty cycle (the heaters are turned on briefly and infrequently). To conserve a little power, sometimes I put my hotel pan on a cooling rack so my granite counters don’t act as a heatsink. If you wanted to make the water bath much larger, perhaps 5 gallons or more, then the insulation might become more of an issue.

Hope this helps.

Scott

Scott, you have done a professional job, I am amazed!

How many hours did that take you to build? What would be the price of your SV-rig if you charged 50$/h?

I wonder how long the relay will work as it has to switch on and off every few seconds. SousVideMagic or Auber PID-controllers use Semiconductor Controlled Rectifiers (SCR) instead of a mechanical relay. If your relay should wear, you might get a SSR e.g.http://www.auberins.com/index.php?main_page=product_info&cPath=2&products_id=9 at 15$.

Indoor fountain pumps in my experience will withstand 60°C

although specifified for max. 35°C. From the experiences of a friend of mine I know they will not withstand 80-90°C. For temperatures above 60°C you may use an aquarium bubbler.

If your container is not well insulated, PID-control is easier than with e.g. a well-insulated rice-cooker, as heat loss counteracts overshoot after initial ramping up or after a disturbance load.

Pedro

Does the CD101 PID have an internal relay? I just ordered one and am worried that Alvin’s result (blown internal relay) will will happen to me after ~60 hours. If I hook up the Auber relay is there a way to bypass the internal relay, if indeed it does exist?

I saw earlier on this post about selling these once you have it refined. Is this something you are going to do?

Scott, very nice work. You should be proud of all the geeky foodie DIY-ness you have inspired. I just finished building and troubleshooting one for myself using a mix between your design and Alvin’s modifications.

I’ve built similar temp control circuits in my grad school research, but I hadn’t thought of applying such knowledge to my hobbies. Now you have me brainstorming how to make a DIY chamber vacuum bag sealer. The FoodSaver systems wear down so fast, while professional sealers are so expensive. It seems like one could put a cheap impulse bag sealer inside a high-density plastic bell jar evacuated by a surplus scientific vacuum pump and you’d have it. The problem I hit with the idea though is you’d need some sort of vacuum feed-through to press down the sealer bar inside the chamber. If anyone tries this idea remember: Safety First!

My first 64.5C eggs are cooking now.

Win a Sous Vide rig !

For lack of contestants, FreshMealsSolutions have postponed the deadline of their “Most Innnovative SousVideMagic Sous Vide Cooker Contest”, so you still have the chance to win a SousVideMagic 1500D plus FreshMealsMagic.

I built the thing.

The temp controller is near impossible to program. Find a smart buddy and pay him royally. Once you get it right it works amazing. Within .1 deg C for approx 4 gallons of water.

Use an igloo cooler to keep the heat in longer. Also, I put the pump on the opposite end of the cooler to help move the water.

Bed Bath and Beyond has the immersion heaters for $8 each in store.

Nice design.

I’m so thrilled that so many folks have taken on this project! Congrats to everyone who completed it succesfully, and welcome to sous vide cooking!

Since the aquarium pump may not be able to handle hot water (180 for duck) for long periods of time, it may be best to create a “reserve” supply of cool water to place the pump in, and use the plastic tubing for the pump that comes with it to feed into the hot water.

A better solution might be to use a regular air pump in the dry unit with the PID, and just feed a steel tube into the hot water. Any suggestions on a non-submersible pump that would work?

Sorry to post again. If there’s a forum or email you’d rather I use please let me know. Why do you suggest the pt100 over k type thermocouple? Is it because K type has a 2.2 Celsius accuracy buffer whereas the pt100 has 0.3? Or is it something more horrific like “k type is made of lead”? 🙂

@Elijah – This is a fine place to ask questions. This way, everyone else can see the answers posted here.

Regarding the aquarium pump, I’ve tested two different models and both performed well during sustained high-heat cooking. So far, I haven’t had a single pump break down.

Non-sumbersible pumps are a little harder to find and are more expensive due to the type of construction they require. But, one alternative I’m looking into is putting a motor in the housing to drive an impeller in the water. This would definitely be temperature safe.

With regard to the thermocouple, I recommend the pt100 purely for accuracy. I don’t know of any food safety issues associated with using a different type of probe, but with most PID controllers you must use a pt100 if you want to control temperature with an accuracy of .1C or more.

Regarding pump breakdowns.

My first pump broke. It was an ‘indoor water fountain pump’ from eBay (http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=290383806514). It was working fine around 65C/150F but broke at 83C/180F. At that higher temperature the epoxy resin within which the pump is enclosed swelled to the point where the propeller shaft jammed solid.

I have since ordered a marine aquarium ‘powerhead’ (http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=300413152308), as recommended by some DIYer. I’m not sure if it will be any better, as AFAIK all submersible pumps share the resin-enclosed design.

Perhaps the safest thing is to use the pump only for meat and eggs where the temperatures are lower and more exact. Next time I try to cook apples, I’ll leave the pump out and allow a small temperature gradient.

My in-progress implementation of the PID controller is here: http://q-m.org/2010/04/08/diy-pid-controller-for-sous-vide/.

Hello again. I got my PID on eBay (http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=180411290166) and it says it’s good with a SSR. I bought the Auber SSR mentioned in an earlier post, but it doesn’t seem to trigger. The internal relay works fine, but I’d like to use the SSR to limit the amount of wear on the internal relay. The ebay listing says the PID supports Voltage Pulse Output, but I can’t seem to find any setting to use this!

Also, does anyone have a complete listing of the CD101 setting code explanations? For example “SL 2” is the setting for Centigrade or Fahrenheit (0000 for celsius, 0001 for fahrenheit). I can’t seem to find info on the others though (SL 3,8,9,10,11).

Since the SSR setup isn’t working, I reluctantly rigged this with the internal relay (posts 4/5) to a GFCI outlet. Last night I tried with a pre-seasoned (teriyaki) and already vacuum 1lb sealed beef shoulder from Publix grocery. I left it in for about 2 hours at 135F. AMAZING texture and flavor after I pan seared the cuts for about 10 seconds on each side. I did eggs at 148F (64.5C) for an hour, but they were kind of slimy. I think I’d increase the temp a few degrees or the time by 15-20 minutes. I also picked up a FreshSaver (http://www.amazon.com/FoodSaver-FSFRSH0055-FreshSaver-Handheld-Vacuum-Sealing/dp/B002NGNBR8) from Walmart for about $16. I’m trying my own garlic pepper & Worcestershire seasoned steak right now!

Elijah/Anyone else –

So using the SSR didn’t work? That was going to be my next step. I’ve been stuck for the last 3 weeks, I just can’t figure out how to finish this thing. I never hear any clicking in my external relay, just the internal relay.

This is all way new to me, so I don’t really understand why there is both an internal and external relay. Why is an additional relay needed?

Can you explain how you set your unit up without the SSR?

I believe Pete W used this SSR and it worked (http://www.auberins.com/index.php?main_page=product_info&cPath=2&products_id=9) any idea why yours does not?

At this point I’ll pay for help! 🙂

Thanks,

Jimmy

Elijah/Jimmy,

If you are hearing your internal relay click then your PID settings are wrong. The internal relay should be inactive when you have the PID set up to run an SSR. Check your manual and change the mode to external relay.

Pete,

I don’t think that’s possible with what I have. On this particular ‘build’ of the CD101, it is set to Relay only, the guide doesn’t mention changing over to SSR, and the company I bought it from admitted they sent the wrong one. In case this happens again, do you know which setting controls SSR and the internal relay?

I love this!!! I have already started my sous vide project using our plan. I am a student chef and I have been looking for a cost effective way to cook using sous vide. I attended a wonderful chefs’ seminar where we discussed the requirements for sous vide. It is important to remember the vacuum bag part of the equation. The ‘Food-Saver’ is universally accepted as sous vide worthy. Zipper bags are NOT. The worst case scenario is the introduction of bad critters into the slow and low cooking method causing the eater to suffer nasty illness.

Elijah,

I am using a different PID than you are so I can’t help you with the setting. Mine has an output setting that you have to change to disable the internal relay and enable the SSR controlling signal.

i replaced my PID with a JLD612, still using the PT100 probe, but I cannot find the setting for 0.1 degree accuracy, anyone know how to set this on the JLD/TET612?

Hey Scott, thanks for doing the writeup!!! I was just looking at the specs for the PID and it says that it is a 24V output, if this is correct how is this working with 120v heaters?

thanks in advance

EM

@erik,

the output of the PID is simply activating the coil on the relay…120v heaters work fine. (off of 120v switched by the relay)

Have you run a test yet to see what the maximum attainable bath temperature is with these three heaters? At some point, is insulation needed, or can make the water boil?

Awesome setup. I’m going to build one at some point for sure. I’ll likely mount the heaters and temp sensor in a plate that is separate from the controller housing. I’m thinking I might then cut the lid in thirds or so, and then permanently attach the heater/sensor plate to that 1/3 chunk of the lid (leaving a notch in the edge of the lid for the pump power cord). I’d then put the controller in an external enclosure that has a 4-position AC outlet on it (can one be independently wired, or are they all wired in parallel?) and tall rubber feet to get it up off the countertop. I personally don’t like the idea of precariously perching 110V electrical components over water, only being secured by a layer of glue… 😉

Hi Scott,

Just make the cooker.

The element stays on for some strange reason. The displays flashes when the temperature goes over the set point. I have adjusted the pid for the pt100 but can’t find where to change the decimal setting.

Can you help?

Hi Scott, first I want to congradulate you on this DIY and how of a great success and fun project it was to follow and built myself. I made a replica of what you have made to kinda feel how it works. I have a basic prototype, nothing is set in stone if I’ll keep your setup to have everything included as one system, or use Alvin’s idea on it.

I have 2 questions regarding my setup. Thermometer and Relay clicking noise.

I have my system set to 60, both green and orange are at 60, continuously every 1-2 seconds intervals the relay keeps clicking on and of. Is this perhaps on the degree of accuracy that I have set it up or is it normal? Also my PID says the temp is at 60, but when I use my digital thermometer, it shows that I’m at 63, so I have a 3 degree variance that isn’t being read properly. Do you have any idea for a solution, or my pt100 might be dead?

Thx in advance!

Also, clicking noise occurs and the OUT1 light keeps blinking together with the relay.

Thank you,

@Alvin I have the JLD612 PID as well, and I have not yet figured out how to enable .1 degree accuracy either, but I found a “manual” for it at http://fhupiora.fhupiora.home.pl/JLD612Manual.pdf

It isn’t very well written, but it does have some useful info, and you might be able to glean enough to figure out the accuracy setting, I couldn’t seem to find it.

I went with the receptacle build that is similar to yours Alvin, but my problem is with the SSR, I don’t know if the SSR is faulty or what, but after wiring it in, I am finding that there is always voltage applied to the receptacle. Using the multimeter I am finding continuity between contacts 1 and 3 which does not make sense since 1 is supposed to be the load side of the relay and 3 is supposed to be the control side of the relay, shouldn’t these be isolated from each other?

Phillip & Ricardo,

You’ll need to go through the settings. INTY will be the one where you can choose the probe you have. There are two different settings for the PT100 in the PID. One is listed as PT100 and one as PT10.0. One of those will be the settting with the extra decimal place (I believe it is PT10.0 but I am not home to check right now).

There is also a setting that will apply a variance adjustment if your temperature is incorrect. However, I wouldn’t automatically assume that the PT100 is the one that is incorrect unless you are using a high accuracy thermometer to calibrate against. Most kitchen thermometers are not very accurate. If you don’t have access to a laboratory level thermometer, the cheapest substitute is a basal thermometer which you can get at most any drug store for about $10.

Hi,

I also noticed that as the temperature reached the set point the out 1 light flashed a couple of times but there was no clicking sound. Is it the relay that is not working properly or the PID controller?

I can hear the relay click on once when I turn on the unit at the beginning and also when I turn off the unit. The alarm light comes on once it has gone a couple of degrees over the set point and then the temperature reading starts to flash.

Hi Pete,

Thanks for the tips. Where can I see those settings? The way I set it up was with the provided pdf file that Scott provided. There I think it was SL1 you can set the codes for the thermometer. I used 1100 for the PT100. I did check my kitchen thermometer that I use. I boiled water and stuck it in and it stayed at 100.7 C which is pretty close to perfect I guess. I will take a look as soon as I get home and see if I can find the variance configuration and see if I can play around with that. Also if possible Pete, can you provide me with the settings you used in Cod0000, 0001 and 0002? Thank you in advance.

Also for everyone else. I found a great discussion about sous vide or cooking with low temps. http://www.cookingissues.com/2010/02/12/sous-vide-and-low-temp-primer-part-i/ is the link. Its very informative and will start giving you some basic principles and ideas on cooking in the water bath.

I just looked at Alvin Schultz’s blog:

http://tnrplaya.wordpress.com/2010/03/02/diy-immersion-circulator-seattlefoodgeek-mk-ii/

and that’s EXACTLY how I want to build mine, with two exceptions:

1) I’m going to use a 2-piece sheetmetal enclosure for the electrics, with safety ground connected to it.

2) I’ll likely just put the heaters and sensor probe in an acrylic or ABS plate that sits across the top of a storage bin and has #10 screws hanging down that engage with mating holes in the rim of the storage bin to make it stay put. If I end up wanting a more generic solution like he built, I’ll do what he did… For now, I just want a nice, stable setup on a specific storage bin that can’t tip over, etc.

Good stuff! Can’t wait! Just bought most of the parts!!! 😉

Everyone,

There is a really in depth discussion on eGullet. It’s over 3500 replies so there is a lot of information there.

http://forums.egullet.org/index.php?/topic/116617-sous-vide-recipes-techniques-equipment/

Ricardo,

Sorry, I misread who posted above and thought you had the same PID as Phillip (I see now it’s Phillip and Alvin that have the same). The manual he posted looks a lot like mine and so I knew how to fix the issue on his. Looking at the manual Scott posted, I am not sure how to fix your decimal place issue. Perhaps Scott will chime back in.

As for the thermometer issue, keep in mind that water’s boiling point can change depending on altitude and whatever minerals or additives are in the water. Your calibration method is probably good enough if you are not going to play with the edges of safety (for instance around 132F for over 4 hours). If you are going to do long term cooking at the low range of temperatures, I would invest in a basal thermometer.

Just wanted to thank Scott again for doing the leg work on this first DIY….truly revolutionary stuff we’re doing here. I had a commenter on my blog from Australia wanting to bring Sous Vide to his restaurant.

So i’ve contacted RKC for original manuals for the CD101. Anyone cares if I email them and they can upload it for future references?

Pete, I fixed my issue with the temperature. Just ad my variance in it and now it perfect.

I’m pretty close to sea level so the digital thermometer works great, but I took your advice on the basal thermometer and its same as my digital one.

Happy cooking 😀

Greetings from Sydney Australia!

I just saw this on Craigslist:

http://sarasota.craigslist.org/bfs/1689921946.html

I knew I’d seen the photo before – Unless this is you selling off your own device it looks like somebody is scamming you.

Cheers,

Peter.

@Peter Thank you for bringing this to my attention! It looks like whoever posted it has deleted the posting, but I’ll keep a look out for scams like that. Thanks very much.

I’d like to offer one comment on an other excellent design. That rocker switch is rated 6 amps at 125VAC. Those three Norpro 559 heaters are 300W each, for a total of 900W, plus 2.7W of the pump and whatever power the pump and PID controller pulls (unspecified, but lets say 7.3W for fun).

Assuming 125VAC, that’d be 7.28 amps. At 110VAC (more likely), that’s 8.2 amps. I think I’d consider looking for a heavier duty switch. Turning on the unit isn’t much of an issue, because you’re not switching the full current (the PID controller is keeping the heaters off). The switch is less likely to fail while it’s running. However, when turning it off, if the heaters are powered, you do risk arcing. You may want to consider turning off the heaters via the PID controller first, the powering it down.

Nonetheless, I would strongly recommend upgrading to a less sexy higher current rated switch 🙂

Your design is just what I needed to get off my butt and build this. Thanks for the great writeup, and for all the helpful comments. I’m going to go with the standard 120V outlet on the controller, so I can use it with any immersion heater, or crock pot. Hopefully this will also make it easier to move between coolers or other containers.

With a sufficiently large and insulated water container (20 or 50 gal cooler) would the pump even be necessary? I’m kind of thinking that once the water was up to temperature, a single immersion heater should be enough to keep the temperature constant.

Given jc’s comment, I think I’ll add a 6A slow blow fuse too, just to be safe.

@JC Great comment! Yes, if you’re building one of these, you may want to invest in a heavier-duty switch rated for 10 Amps or more. Since this was a DIY project done on the cheap, it’s not without shortcuts, hence the big safety warning. Using a lower-rated switch, at the worst, you may trip your kitchen’s GFI outlet or circuit breaker. But if you can find one that fits your budget, I agree with JC: get a bigger switch.

@Bonafidebob Yes, you can certainly get by without a pump for circulation – in fact, the Sous Vide Supreme doesn’t have a circulator and relies only on convention currents for circulation. But, you will end up with pockets of hot and cold areas that will vary as much as 2 degrees C, depending on the shape of your contianer. If you’re cooking for many hours, the temperature will even out over time. But, if you’re cooking eggs, which only take an hour and are very heat-sensitive, you may want to spring for some type of circulation mechanism for best results.

Idea for circulating hot water: stirring.

Instead of using a water pump, try dipping a stirrer. Eliminates heat sensitivity.

My spelling/typing in the previous post was an atrocity…

Regarding the switch: If it fails, it won’t necessarily trip a breaker. It may just burn up. It’s unlikely to get hot enough to ignite the plexiglass/acrylic, but because it’s in series with the load, it probably won’t trip the breaker.

I’ve found a source for heat tolerant pumps on eBay @ http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=260590353981 They’re good to +80C (or they’re claimed to be) or 179F. They stand a better chance of surviving the higher temperatures than the aquarium pumps. The draw back is that you will need a 12VDC power supply for them. eBay to the rescue again: http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=260593436015 (Sorry about using absolute auction numbers, I know they’ll go away eventually. However, a generic search turns up too many wrong results).

My current plan for a sous-vide cooker is using a half-size steam pan, 2 2000W water heating elements in series, the PID controller and PT100 probe, and the above pump. I’m going slow, since I’m doing it on the cheap. The web page is located at http://www.tinymicros.com/wiki/Sous-vide_Immersion_Circulator Email is jcwren jcwren.com if you have questions or suggestions.

@JC Sounds like a plan! FYI, I’ve played with those Camco water heating elements and they are very powerful. The NPT threaded base of those elements gets nearly as hot as the coil itself, so make sure that it is mounted in a metal enclosure using a metal nut.

@JC I used full size 6inch hotel pan i got in chinatown for $18 and a single 1500 watt 120V water heater element (from grainger) mounted in a hole i drilled on the side of the hotel pan. This setup is working great for me and I was worried the 1500 watts might be too much but turned out to be perfect from what I can tell. My accuracy never fluctuates beyond +/- 1 degree and usually stays within 0.4 degrees.

for those using SSR. I ordered this SSR from virtual village:

http://www.virtualvillage.com/40a-ssr-solid-state-relay-for-ac-devices-003602-009.html

they sent this relay:

http://www.photosensor.com.tw/Solid%20State%20Relay/Single%20Phase%20Solid%20State%20Relay%20(AC%20to%20AC%20SSR)(UL)/SSR-40AA.htm

a meter on the SSR output measures about 18v when out 1 goes on, which means it isn’t out puting enough to trigger the relay, right? the second link shows on>45v

So for now, I’ll connect to the J2 output and set OutY to 1 on the TET/JLD 612 PID.

@Alvin, the relay they sent you requires an AC input in the 80 to 250 volt range. It’s basically an AC operated relay for the purpose of switching heavier loads on the high side (don’t know about your electronics knowledge, so if this is dumbed down too far, sorry about that). You might think of this as a relay where you want to switch a large load (like the heaters) with a small switch that can handle only less than 1 amp. You definitely want the SSR-40DA. Unfortunately, Googling around for these models reveals a bunch of conflicting images and data. These are made in China, and subject to translation problems. There are some on eBay that are about the same price with shipping, and generally the pictures more often reflect what you’ll likely get (eBay is my first stop for shopping for a great many things!) Search for “40a ssr” and check the control voltage for being 3-32VDC.

just placed my order for the PID and the thermocouple on ebay, I can’t wait to get the parts so I can get started!!!

BTW I have an idea for using one of the 1500W screw in water heating elements, I will post pictures of my progress.

I ordered a PID from ebay earlier, and I think I have goofed as its got the internal relay rather than voltage output. The issue with the relay is that the current support is low (3A), so it probably needs an external relay anyway.

My electronics is rusty, but couldn’t I use a 120v ac relay instead of the low voltage one you used, and then just use the internal relay to toggle mains power to a higher current relay, say something like: http://www.alliedelec.com/search/productdetail.aspx?SKU=8500190

which should be able to handle a 1.5kw heating element?

@sam Yep, that relay will work instead of a low voltage relay. I’ve tested one with another contorller I’m using. The only “drawback” is that these relays make a pretty loud click, and if I turn the lights off, I can see a blue spark every time it clicks on and off. That said, I’ve got 150+ hrs logged on that relay already and it seems to work like a charm.

I’ve ordered a batch of SSRs (solid state relays) which should be the most durable and long lasting. They’re expensive, but if you order them in quantity, the price isn’t too bad. I can’t wait to see how they perform.

Are you using PIDs with the relay output or a low voltage signal?

So, it looks like http://www.alliedelec.com/search/productdetail.aspx?SKU=6910503 might be an SSR that will switch 10A load from a 120AC signal. If there was a lower voltage output from the PID, I’d prefer to use that for signalling, but I don’t know if that will be available on the one I’ve bought.

Where do you get components – I’m originally from the UK, and it seems allied is the US version of RS (not radio shack) which would be a natural choice there.

@Sam The PID controllers I’m using have both a low-voltage output and a 120AC output. The SSRs I ordered are designed for use with a low-voltage input. I sourced them from eBay from some company that ships from Hong Kong. Still waiting for them to show up…