I fell down the rabbit hole of knife sharpness. For someone with a few endless kitchen obsessions already (ahem, espresso, sous vide, barbecue,

clear cocktail ice) it’s not surprising that I got sucked into sharpness. In my defense, this particular obsession is inarguably more practical: sharp knives make cooking way more fun, and a little bit safer.

The internet is filled with guidance on knife sharpening — some of it good, some of it garbage. [Maybe you’ve seen the targeted ads for always-on-sale knife sharpening rollers and jigs that purport to save you from the tyranny of learning to use whetstones.] But there’s something curious about the pursuit of sharper knives: the world hasn’t converged on a single definition of sharpness. Instead, there are two common ways of defining the sharpness of an edge:

- Geometrically. Zoom way into the cutting edge and measure its angles.

- By cutting stuff and measuring how much force was required.

I prefer definition number two. To me, the point of using a sharp knife is to make food prep easier — specifically, to be able to cut, slice, and chop through ingredients using less force. The geometry of the cutting edge absolutely influences the force required for cutting, but since geometry is difficult to inspect directly, measuring cutting force is a good way to measure sharpness.

The Edge-On-Up tester is a popular sharpness tester among knife geeks, and it kinda works according to this principle. The device is a gram scale that displays the maximum force measured since the last tare, and it’s meant to work with calibrated, disposable filament media that you cut through to measure sharpness. It’s fast an easy to take measurements, and because the media are calibrated, you can compare your knives to strangers’ knives on the internet. So, I think it’s a useful tool in the full arsenal of edge testing. But this measurement only represents the sharpness of a single point on the blade and tells less of a story about how that knife will behave when cutting food. Other factors like the bevel angle, burr, width behind the edge, blade face smoothness, and more will determine the cutting forces required for actual food. Plus, each test gives you only one data point: max force.

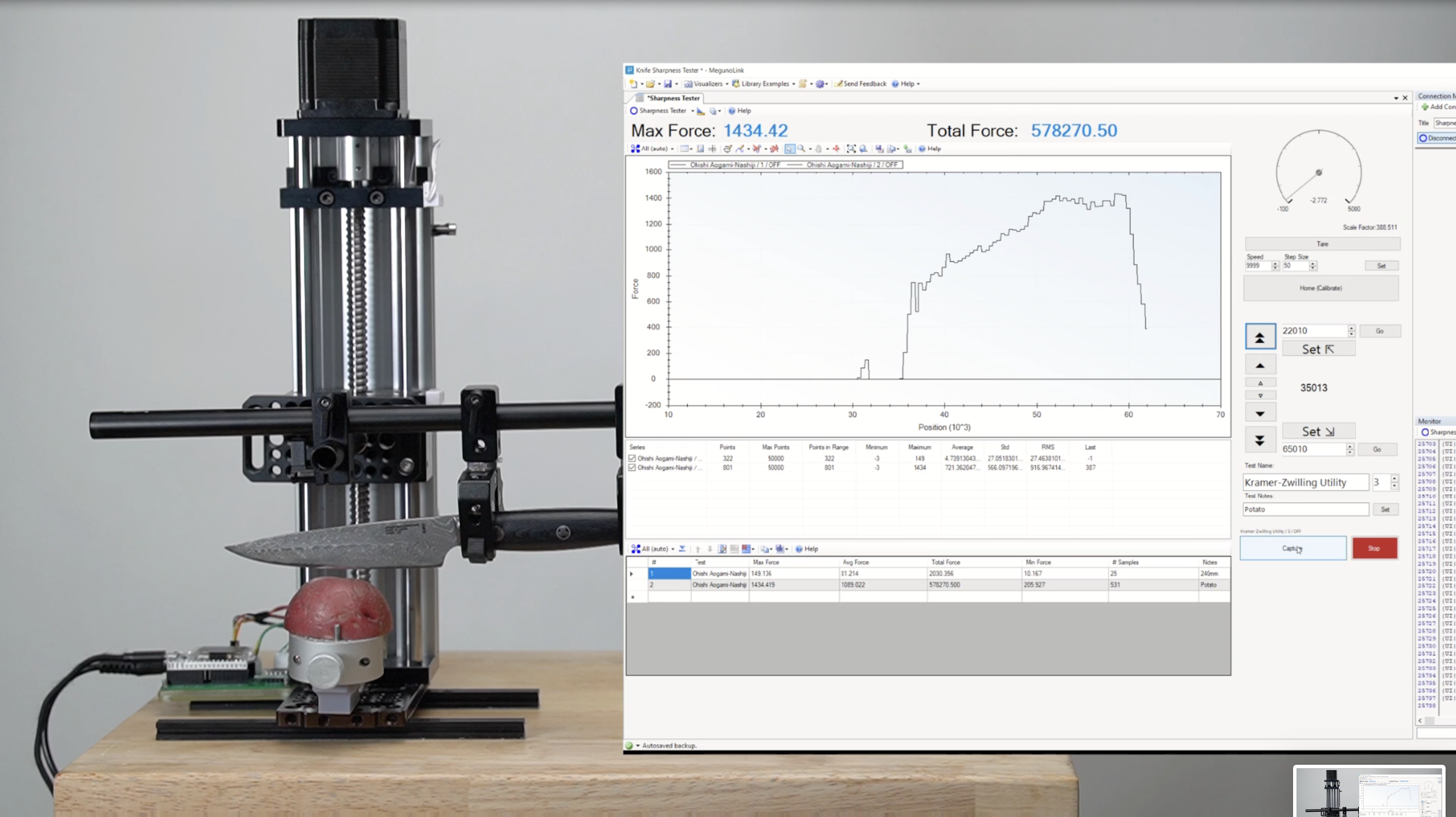

So, I decided to build my own knife sharpness testing robot out of a linear stepper motor, a load cell, an ESP32 microcontroller, some camera rail, and a little custom software. This robot is the lovechild of a CATRA edge sharpness tester and a Texture Analyzer. It works by pushing the knife through a food sample and recording the force at each point of travel. The force is measured by a load cell connected to the microcontroller, and the data are streamed to a PC to plot the results. These plots are richer than the single-point measurements from other testing methods because they reveal differences in, for instance, cut initiation force versus the cleaving and friction forces required once the blade has pierced into the food. The data are exportable for analysis and you can compare not only peak force but also total force (the area under the curve). My robot only performs push cut tests and does not account for slicing performance like some of the fancier CATRA machines but if anyone wants to send me a 6-axis robot arm, I will strap knives to it post haste.

I’m planning to post some data comparing results across foods and blades, and eventually open source the hardware and software required for anyone who wants to build their own knife sharpness tester / texture analyzer / slow guillotine.

Shout out to Dr. Larrin Thomas and his book Knife Engineering which first tuned me into thinking about sharpness in this way.

jqymkd

tu3ijj

peyktt

s4u4zo

voxeab

od5vvc

5tzug2

lfarpd

8x4dqy

2ick3w

lfld6y

lpcz70

qvqnhd